Open-Pit Mine

Khan Altai Deposit

Located at an elevation of 2,600 meters above sea level, it is currently the highest-altitude open-pit mine operating in Mongolia.

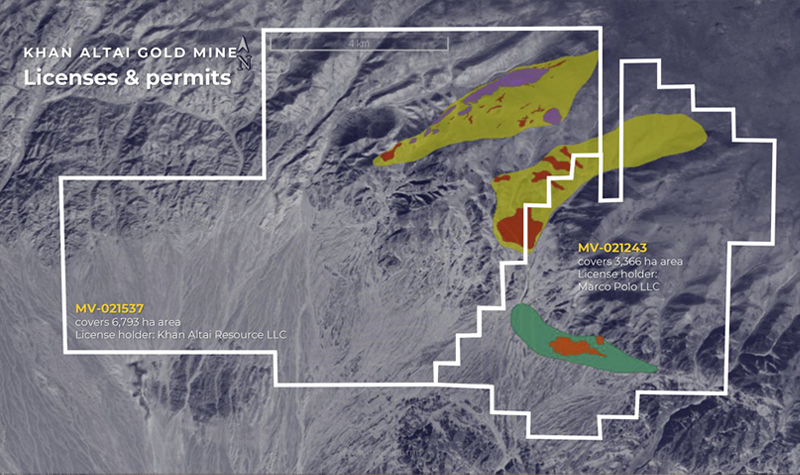

MV-021537, the mining license issued, retains its validity until the year 2050, encompassing an extensive area of 6,793 hectares. This area contains a substantial estimated resource, amounting to 98.58 million tons of gold ore, within which an impressive 86.73 tonnes of gold were identified as of December 2021. The project’s development strategy is characterized by a well-structured two-phase approach:

When evaluating the financial aspects of Phase I, the project demonstrates considerable promise.

The total capital expenditure for this phase is significant, and the financial viability is further supported by a strong net present value, indicating a positive return on investment.

Anticipated sales revenue is substantial, with projected EBITDA also reaching a solid level. These indicators collectively highlight the strong economic potential of the project.

Phase I operation

In this initial phase, the focus lies on establishing a robust infrastructure for processing 3 million tonnes per annum (Mtpa) of oxide gold ore. This primary phase is designed to ensure efficient and sustainable ore extraction and processing.

Phase II operation

Following the success of Phase I, Phase II is marked by the expansion of the operation’s capacity to handle 5 Mtpa of primary gold ore. This ambitious step forward is geared towards further enhancing the project’s economic potential. The MV-021537 mining license, resource estimates, and the structured two-phase development plan together paint a comprehensive picture of a promising mining project that not only secures economic opportunities but also represents a sound investment in the years to come.

Khan Altai Resource

General Site Plan of the Mining Area

We are developing the mining sector to contribute to the advancement of the Western region.

Exploration Drilling & Studies

Around 189,000 meters of exploration drilling and geological studies were carried out, defining and expanding the Khan Altai gold resource base.

Stacked Tailings Facility

A multi-cell stacked facility was developed for safe placement of waste rock and tailings in line with international environmental standards.

4G LTE Communication Tower

A dedicated LTE tower was installed, providing high-speed mobile and data connectivity across the entire mine and camp area.

Mine Haul & Technology Roads

8.5 km of haul roads were opened, enabling continuous ore transportation from the open pit to the processing zone.

Substation & Diesel Power Plant

An electrical substation and diesel generator plant were commissioned to secure backup power for critical operations.

Initial Fuel Station

A fuel dispensing station was built to serve the mining fleet and on-site equipment.

35 kV Power Transmission Line

A 10.8 km, 35 kV overhead transmission line was completed, fully connecting the mine site to Mongolia's national grid.

3 Mtpa Processing Plant

A processing plant with a capacity of 3 million tonnes of ore per year was commissioned as Phase I of the project.

Water Supply & Emergency Pond

A centralized water supply system and an emergency water pond were developed for process, domestic and firefighting needs.

Reagent & Boiler Facilities

Reagent warehouses and boiler houses for both the processing plant and camp were established to support continuous operations.

Greenhouses & Water Treatment

Tree-nursery greenhouses and initial water treatment units were installed to support land rehabilitation and clean- water supply.

460-Person Accommodation Camp

A major camp complex for 460 employees was completed, providing modern, high-altitude living conditions near the mine.

Central Kitchen & Dining

A central kitchen and dining facility were built to serve all camp residents and on-site staff.

MMD Crushing Plant

An MMD crusher with a capacity of 4 million tonnes of ore per year was installed, expanding primary crushing capacity.

Central Mine Warehouse & Workshop

A central mine warehouse and heavy-equipment maintenance workshop were brought into operation.

Processing Plant Laboratory

A modern laboratory next to the processing plant was commissioned for metallurgical testing and product quality control.

COC Office & Social Facilities

The COC office complex, including administration, training rooms, clinic and fitness spaces, was completed to support safe and efficient operations.

6.3 km Ore Conveyor System

A 6.3 km conveyor with a capacity of 1,150 tonnes per hour is being developed to transport ore directly from the pit to the processing plant.

Primary Processing Plant Expansion

A new primary processing plant is planned for long-term operations, increasing overall throughput and efficiency.

240-Person Camp with Wellness Center

A second camp for 240 employees, including sauna and swimming pool facilities, will further improve living standards at high altitude.

Sports Hall, Bar & Outdoor Courts

A sports hall, bar & lounge, and multi-sport outdoor courts are being completed to support employee well-being and recreation.

Fuel Storage up to 1,000 t

Fuel storage capacity is being expanded to 1,000 tonnes, ensuring secure supply for the mining fleet and power units.

Mine Location

The mining site of Khan Altai Resource is located in Naran bagh, Yesönbulag soum, Govi-Altai Province, situated approximately 1,000 km from Ulaanbaatar and 100 km from the provincial center.